Information about our stickers outside

We manufacture our outdoor stickers from Oracal 751 C

ABE:

https://www.orafol.com/products/mixed/downloads/certificates/Car%20windows%20-%20Germany/ABG_751C_D5351.pdf

Surface treatment

The high-quality special adhesives of the ORACAL® self-adhesive materials form a very good bond to almost all clean, smooth, grease-, wax- and silicone-free, weather-resistant surfaces.

Before bonding the ORAFOL® self-adhesive products, the surfaces must be thoroughly cleaned with isopropanol and rubbed dry with a cloth.

Solvent residues as a result of improper cleaning or freshly painted surfaces lead to the formation of gas bubbles between the film and the surface. Therefore, air-dried and baked paints should not be applied within three weeks.

Cleaning agents other than isopropanol are not recommended, as they can attack the paint or reduce the adhesive strength of the films under certain circumstances.

The following is recommended for surfaces that tend to emit gases, such as polycarbonate products:

After cleaning, cover the surface with a piece of film and store it for approx. 24 hours at + 60° C. The plastic will still emit gas if bubbles have formed on the bond after this period. In this case, it is necessary to subject the plastic to heat treatment or to store it under room conditions for a longer period.

If ORAMASK® plotter films are used, the surfaces to be labeled must be thoroughly cleaned.

Isopropanol is preferably used for painted surfaces and vehicle tarpaulins. The exposure time of the solvent should be kept as short as possible, especially on tarpaulins, to prevent it from penetrating the tarpaulin coating. After cleaning, a sufficiently long airing time must be ensured. If multi-colored labels are to be created, it is essential to ensure that the ORAMASK® plotter films are only bonded to thoroughly dried paints. Residual solvents can lead to adhesive residues when the stencil film is removed.

Bonding temperatures

Bonding should take place at the temperature specified in the respective data sheet. In the first 24 hours after bonding, make sure that the temperature does not fall significantly below this. If this is the case, however, post-treatment with a hot air dryer is recommended. Silicone paper removal Place the plotter film cut-out with the film side down on a flat surface and peel off the silicone paper as far as necessary for the initial bonding. Always peel the silicone paper off the film, never the other way around!

https://www.orafol.com/products/europe/de/application-instructions/Hinweise_Plottermaterialien.pdf

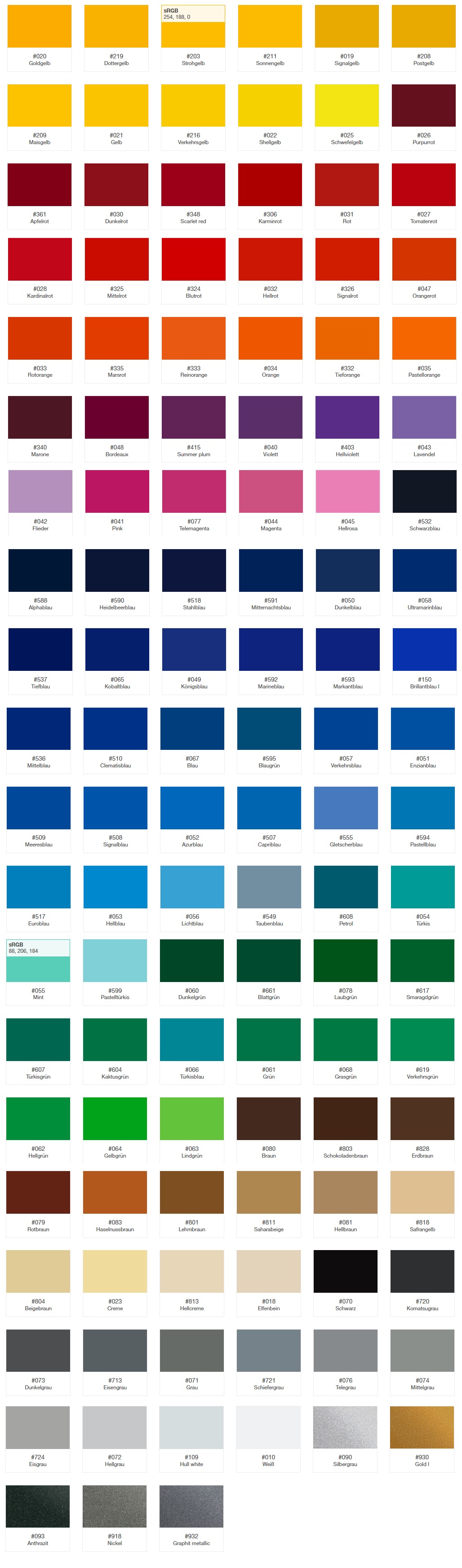

Available colors on request:

Product description

Cast high-performance PVC film for plotter applications with optimal cutting and processing properties.

Specially developed for labels, markings and decorations. Particularly suitable for high-quality vehicle and transport advertising. The special adhesive allows bonding to painted surfaces (flat, uneven, curved) as well as in corrugations and over rivets.

High-gloss surface, additionally white and black in matt. 751C is suitable for digital thermal transfer printing (with resin tapes).

Cover material

Special silicone cardboard coated on one side, 137 g/m², which ensures easy removal of the waste grid. For white film, a light blue coated silicone cardboard is used to achieve a stronger contrast to the writing.

Pressure sensitive adhesive

Solvent polyacrylate, permanent

Certificates

General type approval (ABG) according to § 22a StVZO (~~~D5351)

• Fire behavior according to DIN EN 13501-1 (B-s1,d0: flame retardant, no/little smoke development, no dripping)

Technical data

Thickness (1) (without protective paper and adhesive) 0.060 mm

Dimensional stability (1) (FINAT TM 14) bonded to steel, max. 0.15 mm shrinkage

Temperature resistance (2) Bonded to aluminum, -50° C to +120° C, no change

Seawater resistance (DIN EN ISO 9227) Bonded to aluminum, no change after 100h/35° C

Solvent / chemical resistance At room temperature, 72h after bonding to aluminum, resistant to most ... Alkali

Adhesive strength (1) (FINAT TM 1, after 24h, stainless steel) 18 N/25 mm

Tear strength (1) (DIN EN ISO 527) Longitudinal: > 19 MPa Transverse: > 19 MPa Elongation at break (1) (DIN EN ISO 527) Longitudinal: > 120%

... > +8° C

Maximum durability with professional processing and proper care and use applies to vertical outdoor weathering.

(4) Please note the additional information at the end of this data sheet.

You can find more information at: www.orafol.com/gp/europe/de/support

Black / white: 8 years

Transparent / colored: 7 years

Metallic: 5 years

Gold L, brilliant blue 3 years

(1) Average value (2) short-term exposure (3) in original packaging, at 20° C and 50% relative humidity (4) normal Central European climate

Additional information to be observed

The information provided above is based exclusively on our current knowledge and experience. They do not represent an agreed quality, nor the assurance of certain properties or a guarantee of quality and/or durability with regard to our ORAFOL® color films.

When processing (bonding and removing) as well as caring for and using ORAFOL® color films, our current processing guidelines and care and usage conditions (each available at: ORACAL® 751C High Performance Cast Technical Data Sheet 2018/08 Page 2 of 2 ORAFOL Europe GmbH - Orafolstraße 2 - D 16515 Oranienburg - Germany graphic.innovations@orafol.de - www.orafol.de www.orafol.com/gp/europe/de/support) must be observed and complied with, as otherwise, in our experience, the maximum durability information in particular cannot be achieved.

Further information on the expected maximum durability is contained in the processing guidelines (see section 2 there). If the processing guidelines and care and usage conditions are not complied with, a warranty and liability are excluded. If you have any further questions, please contact a specialist workshop or our customer support. Our goods are traceable in accordance with ISO 9001 using the roll number.

https://www.orafol.com/products/europe/de/technical-data-sheet/oracal-751c-high-performance-cast-3458-technical-data-sheet-europe-de.pdf